What to Shop for in Cabinet Hardware and Millwork

http://decor-ideas.org 03/30/2014 03:23 Decor Ideas

Once you’ve decided whether your cabinets will be painted or stain-grade, how the boxes and doors will be constructed, and what style of doors they’ll feature, there are still some final decisions that need to be made. The cabinets’ hardware and millwork will help determine how the units look and function — and will also have a big impact on the cost.

Hardware. Hardware has come a long way from the days of visible, face-mounted hinges and no drawer guides. (Drawers would just slide over internal wood supports.) Now consumers can choose from a panoply of beautifully engineered and inventive options.

Hinges. Most cabinets sold now don’t have visible door hinges. These concealed workhorses fit neatly into routered spaces inside the door, and some interesting upgrades are available.

The simplest concealed hardware is usually still adjustable, allowing up-and-down and side-to-side movement on the cabinet face, so that the doors can line up with no obvious gaps. Over time they may go out of adjustment, so having the ability to tune up your cabinets with just a screwdriver is a nice option.

Some hinges are soft-close, meaning that the hinge catches the door before it slams into the cabinet box, and slowly allows it to finish closing. This is useful not only for noise control, but also to prevent your doors from breaking from repeated banging over the years.

Guides. Drawer guides, also called glides or slides, come in a variety of materials and functions. The least expensive are made of plastic and metal, and may open only 75 percent of the way, leaving a quarter of the drawer still in the cabinet. These guides may also not be strong enough to carry heavy loads, like lots of dishes or canned goods.

All-metal guides can carry more weight, but additional considerations, like the kind of rollers (nylon, metal or ball bearing), can impact performance. Full-extension guides allow the drawer to be opened completely. Making sure the guides can carry the likely weight of the drawer and its contents is important for long-term performance. There is also an opportunity to make these soft-close, which adds to the cost.

If you have inset or partial-overlay cabinets, the guides may be installed on wood blocks inside the cabinet to line up with the drawers. With full-overlay or Euro-style cabinets, the guides are mounted directly onto the cabinet box to maximize space inside.

Specialty hardware. The biggest conundrum in any kitchen is the corner cabinet. How can you access everything in there? Shelving? Lazy Susan?

While both of those options are still regularly used, some innovative new hardware fittings allow the space to function at its highest potential.

There are some great pullout options that display the contents of the cabinet. You’ll also find specialty options, like lifts for a KitchenAid mixer (and other work surface extensions), pull-down shelving for high cabinets, pullouts for trash and recycling, tilt-out panels for sponges, units for storing canned goods and even in-counter composting. Be sure to ask about all of the options.

Millwork. When your cabinets arrive for installation, the first thing that will happen is that the boxes are installed — often using small, thin pieces of wood called shims to make everything level. Once the boxes are in, the final finishes will be installed, making up the millwork portion of the cabinets.

Millwork can come in stock dimensions and profiles, can be produced to match existing trim in other parts of the home or can be made new.

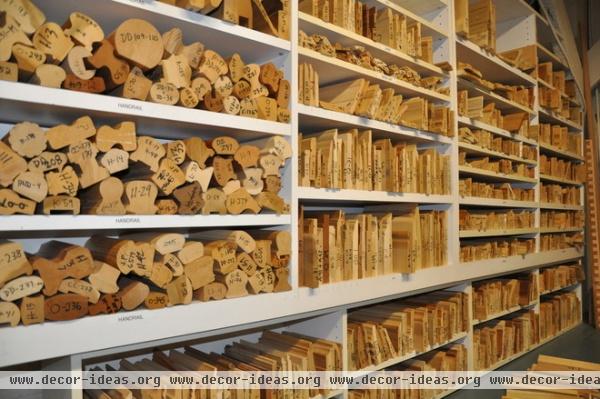

O.B. Williams Company in Seattle has an enormous millwork library with many of the profiles it has made over the years.

The knives used to mill the wood are saved, so that a profile can be selected and milled again. Or new custom molding can be made.

Crowns. Crown molding is often used at the top of cabinets to create a finished crown around the top. Crown molding can be elaborate or very simple. The key is to make a deliberate decision when the cabinets are ordered about whether the upper cabinets will go to the ceiling (with the crown installed flat against the ceiling) or held off from the ceiling by a few inches or more, leaving a space between the crown and the ceiling.

A primary reason for the height falling short of the ceiling is uneven ceilings, which most older homes and, unfortunately, some newer homes have. If you would like a flush (flat-with-the-ceiling) installation, the ceilings need to be level. That might mean adding on to the ceiling joists so that when Sheetrock is installed, the ceiling is perfectly flat and level. Some would rather avoid this added cost, so they opt to end the cabinets lower.

One more thing to consider at the top of your cabinets if they stop short of the ceiling: a plywood cap. Plywood can be installed inside the crown, so that it’s not visible from the front, but so it covers the top of the box, which is generally uneven and a dust collector. This is particularly important if there are adjacent stairs that make the tops of the cabinets visible, or if you want to display items on top of the cabinets.

Valances. A valance serves a similar purpose on the bottoms of upper cabinets. This piece of wood is usually mounted on the front of the cabinet below the door to conceal undercabinet lighting and to block the view of the unfinished cabinet bottoms. There may be different valance options, so ask.

Scribes. These are also known as filler pieces and are made out of the same wood species or painted the same as the rest of the cabinet. Scribes are used to provide a little wiggle room where the cabinets come together and where they meet the walls. They are cut to size and fit tight to adjacent walls, cabinets and some appliances to create a truly built-in look.

Toe kicks. A toe kick is the finish material installed in front of the cabinet base. It’s usually the very last piece of cabinet millwork installed, and goes in after the finished floor.

After the millwork is in, all of the doors and drawers can go back on, as they are usually removed when the boxes are installed to avoid damage.

Inserts. The final pieces installed with cabinets are inserts — like knife blocks and plate organizers — and the knobs and pulls that allow you to open all the doors and drawers.

Handles can be large, flashy, understated or whimsical. The important thing is that they work with the design of your cabinets, don’t impede the opening of adjacent cabinets (which can happen) and aren’t pocket catchers (meaning they don’t catch your clothing as you walk by or make it difficult to use surfaces).

Knobs and pulls can be a nonissue if you have cabinets that are designed to be opened via grooves on the edge of the door or drawer, or if you have push-activated openers that do not require a pull. It’s useful to decide about this before you order your cabinets, to make certain what you choose will work as expected.

Knowing the subtleties of cabinet construction and finishes will help you make decisions that fit your budget, your lifestyle and your aesthetics. Whether custom, semicustom, off-the-shelf or ready-to-assemble stock cabinets, there are many, many options to make your cabinets work best for you.

More:

Choosing new cabinets? Here’s what to know before you shop

Learn the Lingo of Kitchen Cabinet Door Styles

Painted vs. Stained Kitchen Cabinets

Related Articles Recommended