Woodipedia: Make a Solid Choice With Oak

http://decor-ideas.org 11/10/2013 15:10 Decor Ideas

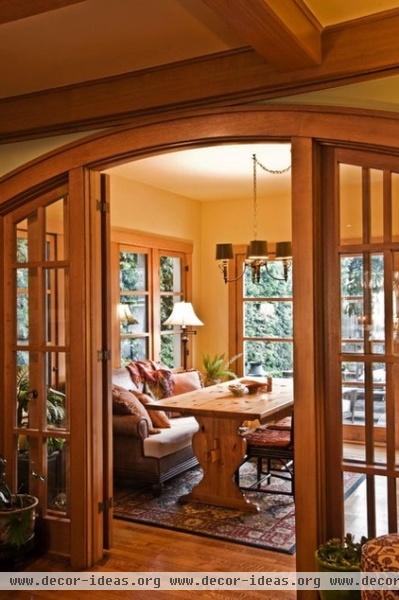

Red and white oak have a strange history of being some of the most prized and reviled domestic hardwoods. Whether people love it or hate it depends largely on the way the wood was milled by the sawyer, matched by a craftsperson and ultimately finished. Sophisticated and labor-intensive techniques have resulted in museum-quality furniture made by Frank Lloyd Wright and Gustav Stickley. On the other hand, low-end production techniques in previous decades led to an abundance of poorly matched coarse-grained kitchen and bathroom cabinetry.

But oak is versatile and packed with potential. It's also relatively inexpensive and durable, making it a go-to choice for flooring and other applications.

Perhaps more than any other wood species, oak has an unusually broad color range. It can have a warm honey color, a shiny reddish overtone, a sophisticated and subdued whitewashed hue or a deep mellow brown tone.

The differences between red and white oak. There are two basic types of domestic oak: red oak (Quercus rubra) and white oak (Quercus alba). Yet despite their names, red and white oak are not always easily distinguished by color. The most reliable identification is pore size: Red oak has larger pores.

Both types of oak are extremely open-grained woods. Even when sanded to a highly polished sheen (like the wood pictured here), they will feel smooth when you run your hand over them, but you can still catch your fingernails in the valleys.

Red oak basics: A vast majority of kitchen and bathroom cabinets in the 1970s and 1980s in the U.S. were crafted out of red oak due to a steady market for new suburban homes coupled with the overwhelming abundance of red oak in domestic forests. Homeowners liked the warm, homey tones and the solid feel of genuine oak.

Much of the wood was milled in a manner called flat sawn or plain sawn, in which the board is cut into vertical slices. This produces the most amount of usable lumber and also highlights a particular distinguishing feature of red oak: cathedrals. These are a progressive series of highly pronounced coarse-grained arches that usually are darker than the rest of the wood.

Premade red oak cabinets became known as contractor-grade cabinets, because they were relatively inexpensive and widely available, but mass-production techniques did not always result in the best grain matching.

As consumers became savvier, the typical mishmash of straight and cathedral grain patterns typical of low- to medium-end red oak cabinets became more glaring, overriding the previously pleasant satisfaction of having wood cabinets in the kitchen.

Red oak has medium to large open pores. You can actually dip one end of a 1-inch-diameter, 5-inch-long stick of red oak into a soap solution and blow bubbles out of it.

White oak basics: White oak has an inherently straighter grain pattern than red oak. Even though it too has an open grain pattern, it is nonporous due to the presence of tyloses, which seal cells as the tree grows. Consequently, white oak doesn't have the internal blowing-through-a-straw effect of red oak. That's why white oak is the favored choice for wine barrels and shipbuilding. Both oaks are used in furniture, flooring, architectural millwork and cabinets.

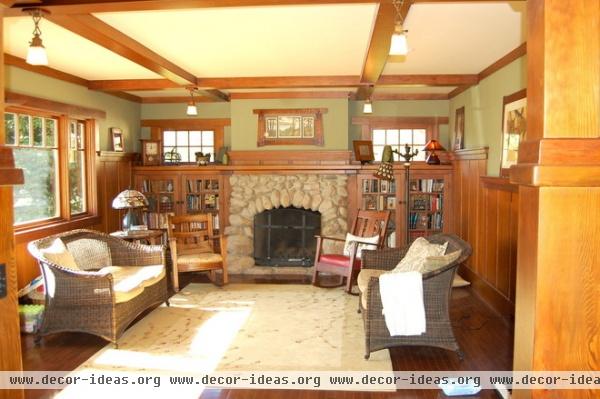

More than any other domestic hardwood, white oak is frequently mentioned in terms of how it is milled. You'll frequently hear of rift-sawn" or rift-cut white oak, which refers to a milling method in which a log is cut in a way that maximizes the amount of straight grain. Quartersawn not only emphasizes the straight grain, it also showcases the fantastic medullary rays that are characteristic of white oak. These are the lighter-toned wavy ripples or ribbons that run across the grain, also known as ray flecks.

Quartersawn white oak is the signature wood of Mission-style furniture, and is a hallmark of Stickley's in particular. (The cabinet shown here is a Stickley-inspired design in quartersawn white oak.)

Another type of white oak is imported French oak. Extremely expensive, it has an exceptionally tight grain pattern, because it typically comes from old-growth European oaks.

Cost: White oak is slightly more expensive than red oak, but according to Walt Maas, manager of Bohnhoff Lumber in Vernon, California, they both run around $2.90 per board foot. Maas says that imported French oak (also known as European oak) costs roughly $10 per board foot. "That price makes domestic white start looking better," he says. "White oak and French oak are much more similar than they are different."

Durability: The Janka rating measures the resistance of various wood species to dents and dings. Hard maple, the most durable of American hardwoods, has a Janka rating of 1,450; white oak has a respectable rating of 1,360. Red oak is rated 1,290. By comparison, walnut has a 1,010 rating.

Red and white oak are both flooring favorites because of their toughness, pricing and ability to nicely accept a wide variety of stains.

Finishing: White oak is particularly amenable to specialty finishes, such as cerused oak, limed oak and pickled oak. White is generally a favorite color to apply. Sometimes the wood is first wire brushed to accentuate the topographical hills and valleys between the soft and hard grains within a board.

Fuming: A classic method of finishing quartersawn white oak is to fume it to enhance its ray fleck. In this process the white oak is placed in a custom-size airtight tent (usually made of heavy plastic ) along with a small tray of industrial-strength ammonia.

Woodworker Mike Ceja of Los Angeles fumed the white oak shown here for two days, producing this richly dramatic look. "The effect is not just on the surface of the wood," he says. "It penetrates deeply, so you don't have to worry about losing it if you accidentally scratch the surface."

While it's possible to fume red oak, the technique is much more effective with white oak, because white oak contains more tannic acid, which is what the ammonia interacts with.

Sustainability: Oak trees comprise more than half of the total hardwood forests in the U.S., making them a preeminently sustainable species. While red oak is more prevalent in the forest than white oak, both are commercially viable.

Related Articles Recommended